Decontamination of radioactive or biowaste of all hazard classes

We have created a prototype of a fundamentally new installation of a plasma electrolysis system

for processing liquid radioactive waste or biowaste of all hazard classes.

At the moment, the cost of processing highly radioactive waste from nuclear power plants and uranium enrichment for defense purposes is from $ 600 per kilogram.

And existing technologies do not relate to the present disinfection of radioactive isotopes, but only to their processing and packaging in protective containers or dilution of radioactive materials with inert filler, as well as packaging them in protective containers with subsequent burial in specially equipped burial sites.

However, there is a recycling option based on the separation of waste into substances that can be obtained in industry, and the separation of substances unsuitable for further processing, but still very dangerous.

These are wastes that are no longer good, but are still dangerous, and they also need to be disposed of – buried. But in fact, this is not disinfection, but only conservation, packaging and burial, which can later turn into an environmental disaster. The main disadvantage of existing technologies is the high cost and lack of real decontamination.

Specialized plasma electrolysis plant for decontamination of liquid radioactive waste “PACTOL”

Many of our predecessors tried to solve the problem radically and create installations that accelerate the decay of radioactive substances to stable ones elements due to the K-capture induced by the installation. There were even working laboratory prototypes, but they all had several drawbacks nullifying their efforts and making it impossible to use their devices. There were two main drawbacks — they are: huge power consumption and low device life is mainly due to electric arc erosion of electrodes.

The advanced technology created

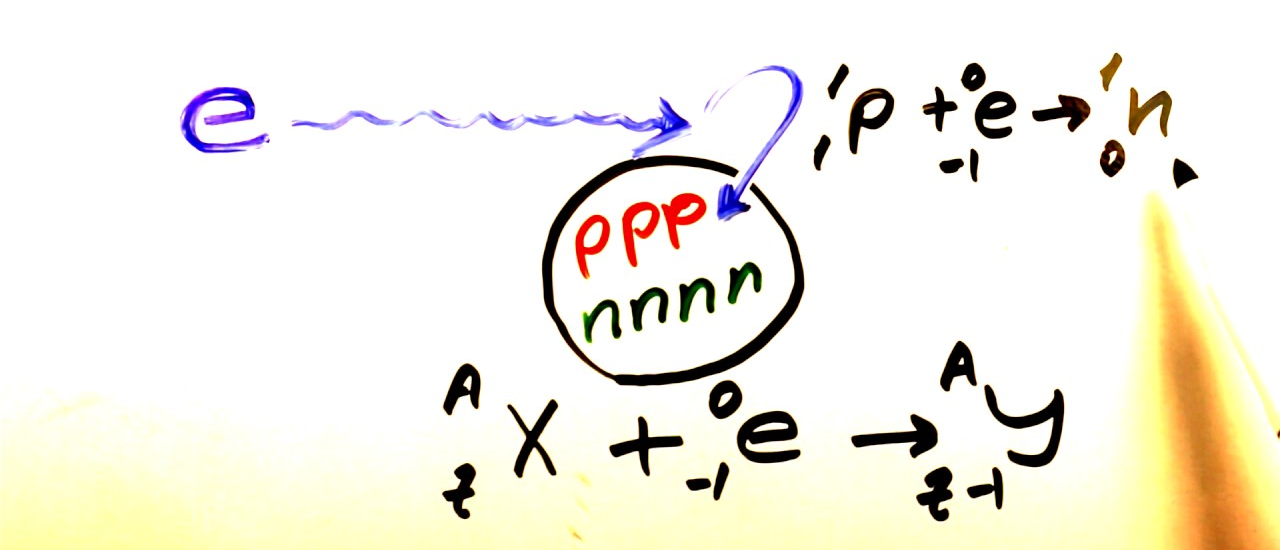

It has become possible to accelerate those processes of decay, and so, that some go in the “soft mode” through the most secure channels, and some even on non-radiative, and in a controlled and well-managed variant that allows inducing K-capture and subsequent decay in addition to the same cesium-137 and tritium 137Cs – > 137Ba + e + v (caesium decays into stable barium-137), T – > 3He + e + v (tritium decays into stable helium-3, electron and electron anti-neutrino).

The technology has also been developed “liquid electrodes”, which is essentially a Know-How. Thus, it was possible to solve the problems of predecessors and create prototype of an almost fundamentally new plasma electrolysis system installation for processing liquid radioactive waste.

What has been done to date

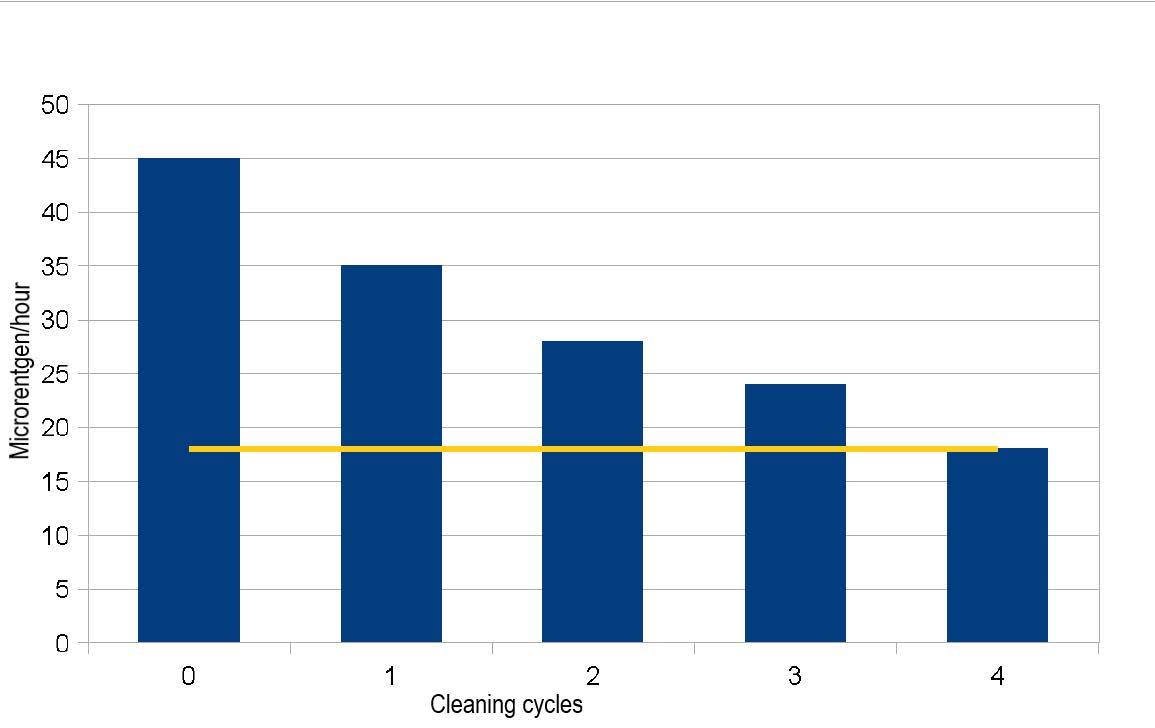

1. An experimental set-up was created, where the result was obtained: reduction of specific activity of radioisotopes, for example, on solutions,containing an admixture of K-40 and I-131, it was possible to reduce their activity to the level of background radiation. Positive results were also achieved on soluble Th-232 compounds. The decrease in the activity of radioactive isotopes was approximately 20% per one decontamination cycle.

2. Reduced installation power consumption by an order of magnitude compared to developments of predecessors.

3. Start-up – “ignition” of the plasmoid with 100% repeatability is provided.

4. The problem of electrode erosion has been completely solved – the service life of the unit has been increased hundreds of times.

5. A stable yield of oxide polymetallic powder was obtained consisting of stable, non-radioactive isotopes.

That makes it possible to reduce the cost of LRW processing

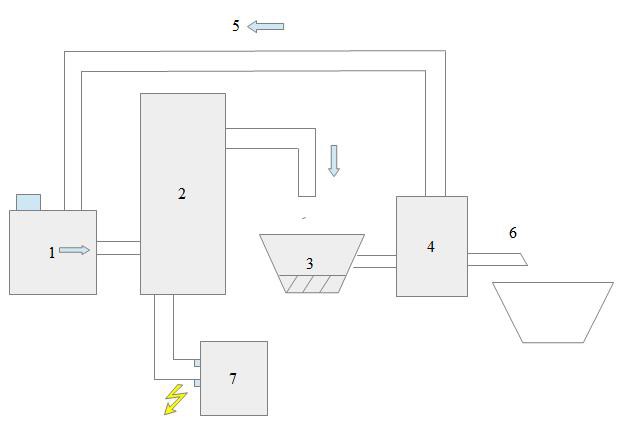

Possible version of an industrial plant intended for cleaning LRW, including water

contaminated with radioactive nuclides

The total cost of processing highly active LRW per 1 kg will be less than $2, which will reduce the cost of processing by more than 300 times for low-level products, including contaminated water, the cost of processing can be less than 0.1$ per 1 kg, since the installation does not require expensive expendable aterial.

1-LRW preparation and loading unit,

2-plasma electrolysis reactor deactivator,

3-sump for collecting coagulated non-radioactive sediment,

4-block of osmotic treatment of water from salts,

5-return of the masterbatch solution in the technical process,

6-output of purified water,

7-supply of electricity.

Main advantages of our technology:

1. Cheapness of processing.

2. Real decontamination, not burial. At the output, only non-radioactive

substances-purified water and oxides-polymetallic powder.

3. Does not require expensive consumables.

4. The versatility of the installation will allow you to deactivate not only radioactive waste, but also chemical waste.

5. It is possible to use the unit in the mode of disinfection of drinking water that will destroy all known viruses and bacteria.

6. Low power consumption.

7. Long service life of the installation